Replacing Structural & Lightweight Fill

Engineered CUPOLEX® Solutions to Structural & Lightweight Fill Replacement

OVERVIEW

CUPOLEX® replaces expensive and time-consuming engineering of structural and lightweight fill required to support floor slabs on grades or on structural decks.

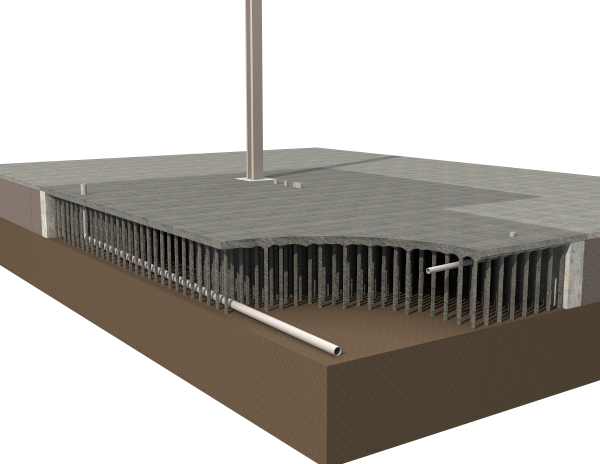

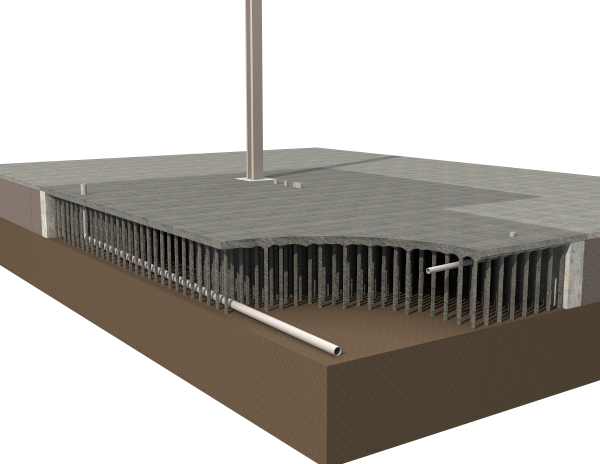

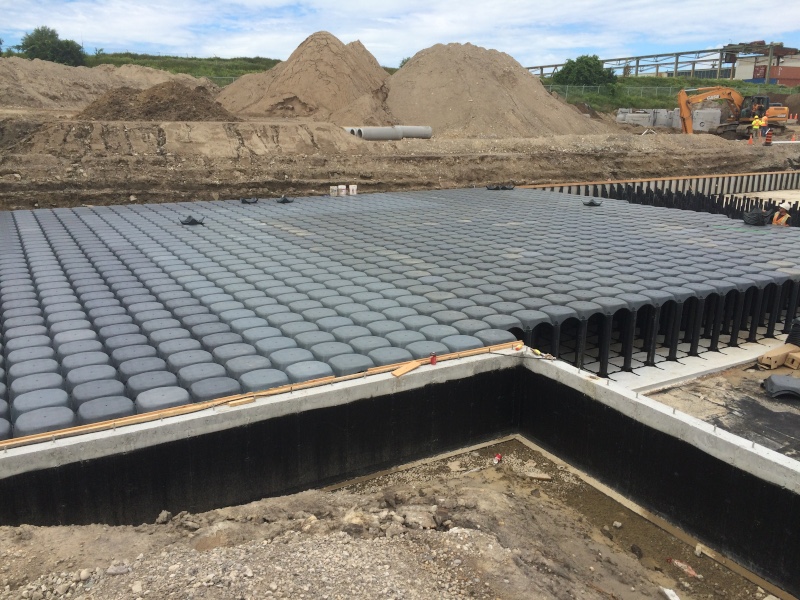

A engineered CUPOLEX® system provides an easy, efficient and fast solution for replacing structural or lightweight fill. The CUPOLEX® engineered floor system can be designed for depth up to 2.5m (100 inches). The cutting-edge forming system is very simple to assemble, quickly interlocks and connects to each other composing a self-bearing structure ready for the placement of the engineered concrete floor slab. The engineered elevated CUPOLEX® formed concrete floor slab supported by the matrix of arches, ribs and columns formed by the system is designed for any load bearing requirements.

FEATURES

The elevated concrete floor slab structure and the void created below the floor slab can also be used for various purposes and applications, such as : stormwater capture, sub-floor utilities, HVAC systems and sub-floor soil gas mitigation venting systems.

Replacing Structural Fill

Though improperly compacted fill is the top cause of structural failures, it is also avoidable. CUPOLEX® can help you with the worst soil conditions

BENEFITS & ADVANTAGES

- Eliminates potential environmental concerns due to possible contamination of existing or imported soil fill that can generate methane when high organic content soils or putrescible materials (garbage) may be a concern

- Eliminates geotechnical concerns related to poor soil bearing capacity and structural settlement

- Eliminates financial concerns due to excavation and disposal and/or increased construction costs.

Replacing Lightweight Fill

CUPOLEX® replaces expensive and time-consuming engineering and placement of lightweight fill required to support slabs on building structures.

BENEFITS & ADVANTAGES

- CUPOLEX® replaces expensive foam insulation and EPS blocks typically used for creating these floating concrete slabs when weight limit is a factor.

- CUPOLEX® also reduces the “dead load” on top of the structure and eliminates the need for costly design analysis and construction methods associated with higher strength, load bearing structures.

- CUPOLEX® is well suited as a structural void fill in concrete forming operations.

- Concrete Crews can easily fabricate virtually any shape or slope and any elevation changes can be accommodated.

Customized Design Package

Design Application Analysis – Our firm helps clients determine the Engineered CUPOLEX® system solutions that address specific site needs.

Value Engineering – CUPOLEX® works with value-engineering at the forefront of each project. We provide the best alternatives for every project.

Structural Systems Evaluation – Every project is unique. Our team reviews multiple structural CUPOLEX® systems to determine the best fit for each project.

Preliminary Structural Design – We work with our clients and their designers to determine the performance of a given CUPOLEX® structure under the prescribed loads and/or other effects or requirements while using principles of statics, dynamics and mechanics of materials to determine the size and arrangement of CUPOLEX® structural elements.

Material & Cost Estimating – Our collective experience helps us to provide our clients with material recommendations to reduce costs while maintaining the function of the CUPOLEX® structure.

Engineered Design Drawings – Issued for construction (IFC) and supported with FEA structural calculations, PE stamp, construction documents and specifications.

CUPOLEX® Installation Shop Drawings – With detailed CUPOLEX® formwork installation procedures issued to contractors.

Onsite Support – Construction training, monitoring and inspections for successful construction, and we present the information in a comprehensive report.

Construction Administration – We provide responses to request for information and interpretation of CUPOLEX® design drawings, with completion statements and regulatory compliance reporting where required.

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Civil Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Civil Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()