Thinking Beyond Standard Mitigation Systems

Passive & Active Systems

Pre-emptive Systems

Radon Ready Systems

World-Class VI Experts

Leading the Way

We are recognized as a pioneer in adopting and standardizing the latest advancements in our field

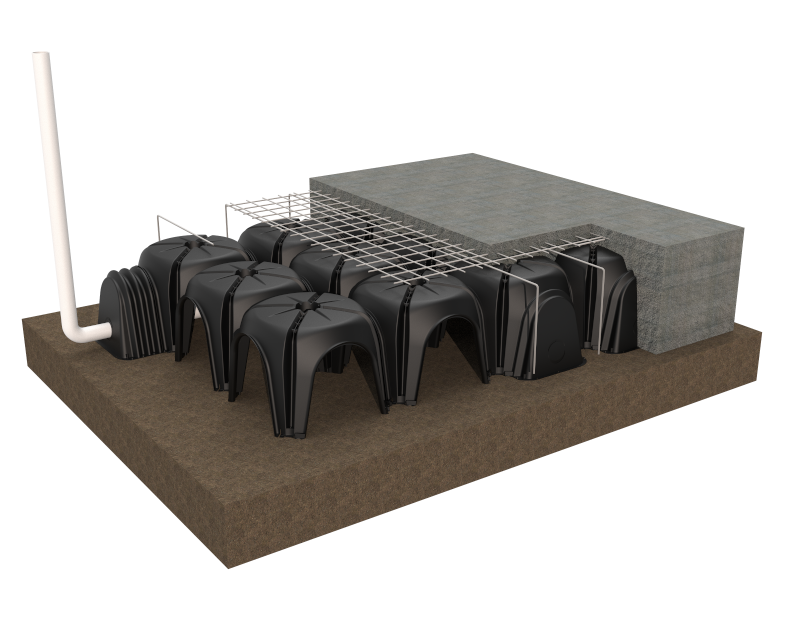

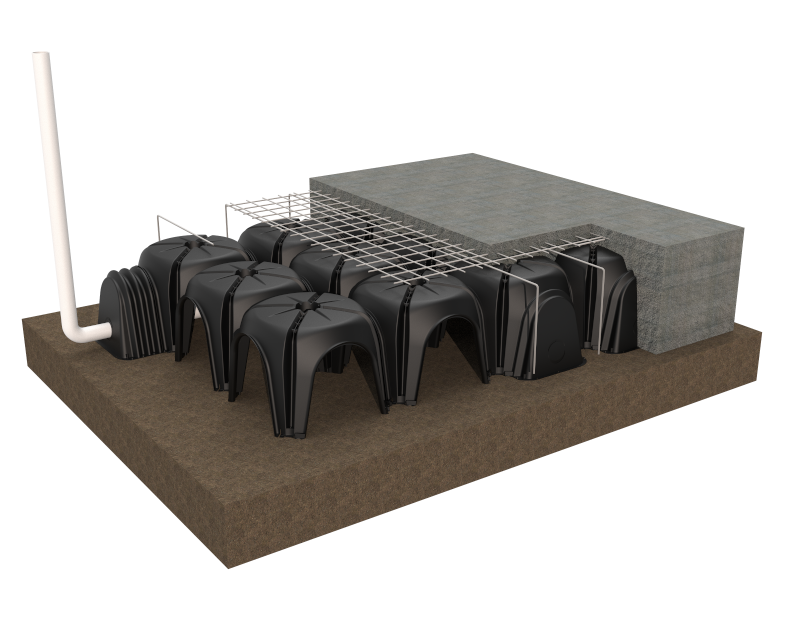

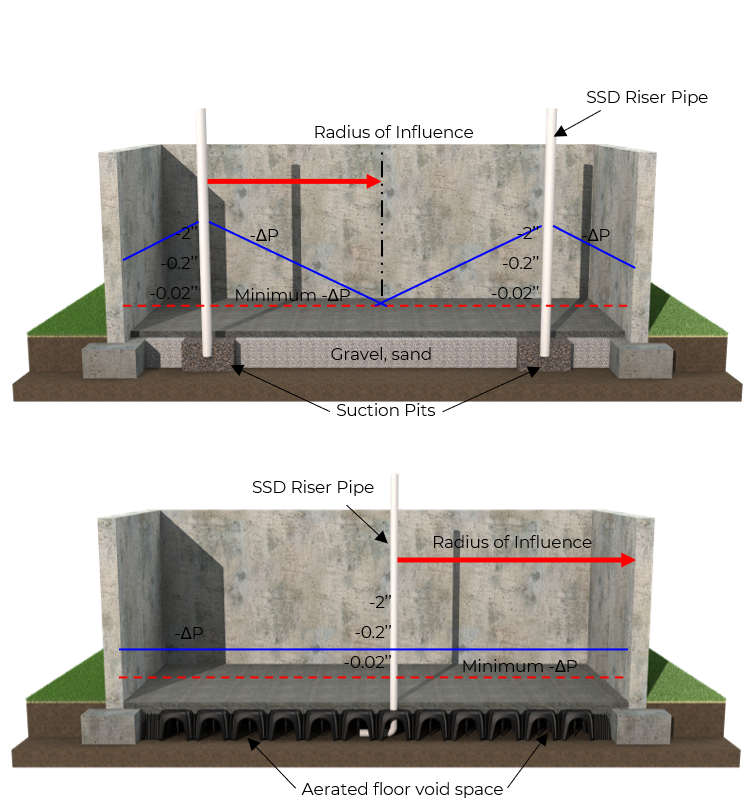

CUPOLEX® is the leading global manufacturer of concrete cast-in-place aerated floor forming solutions for VI mitigation systems. CUPOLEX® pioneered the use of passive and active aerated floor VI mitigation systems using our proprietary form-base methodology. CUPOLEX® mitigation designs provide a continuous void space below concrete floor slabs by manipulating the geometry of concrete – creating an aerated floor that provides better venting and protection at lower cost than traditional systems.

We deliver value engineered and cost-effective vapour intrusion mitigation design solutions for converting challenging sites such as brownfield developments into productive properties. From coast to coast, we lead the industry with the most aerated floor systems designed, installed, and operating efficiently.

Efficient, Innovative and Green

CUPOLEX® is a proprietary patented plastic concrete forming system manufactured by Pontarolo Engineering Inc. The concrete forms are part of a design package provided by CUPOLEX®. Our engineers design the aerated floor slab using CUPOLEX® structural dome technology. We select the type and size of CUPOLEX® forms that will provide the ultimate performance for your specific project. CUPOLEX® supplies the forms to contractors to assemble the system as to the design and specifications provided by the CUPOLEX® design engineers.

With thousands of commercial, industrial, and residential buildings mitigated using CUPOLEX® within the last 20 years, our professional CUPOLEX® engineers know where to find cost-saving opportunities while maintaining or improving system effectiveness.

ADVANTAGES

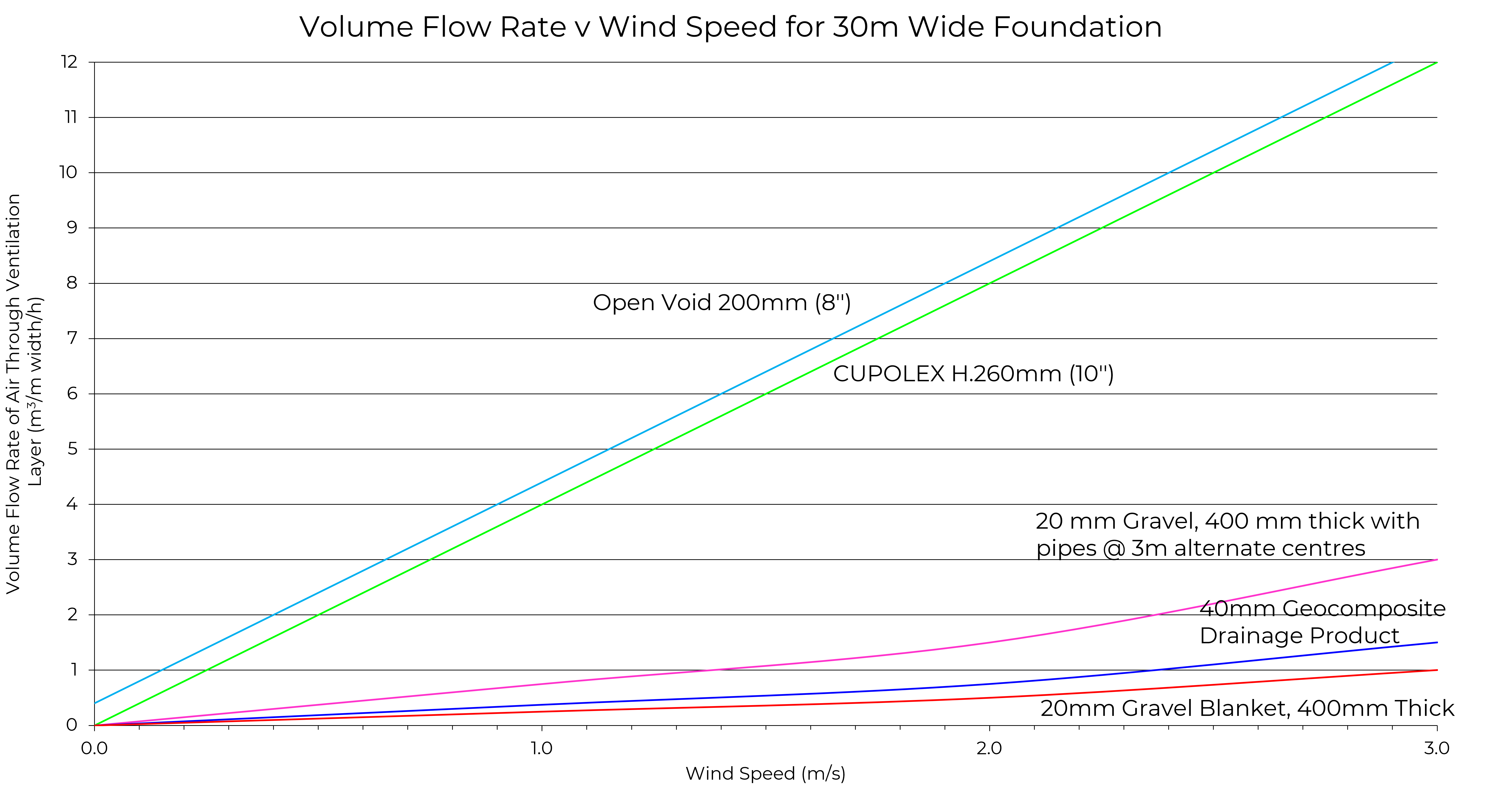

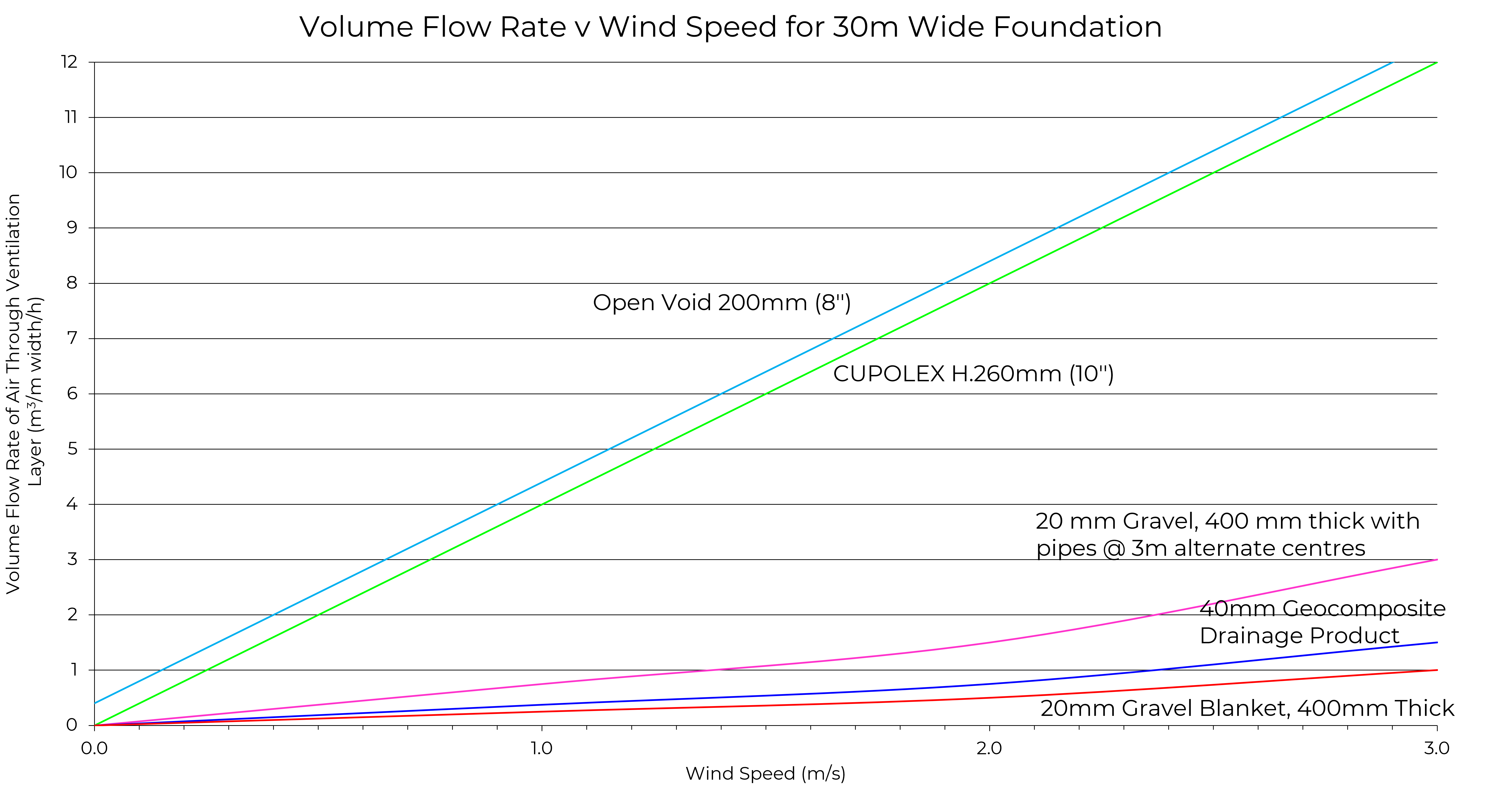

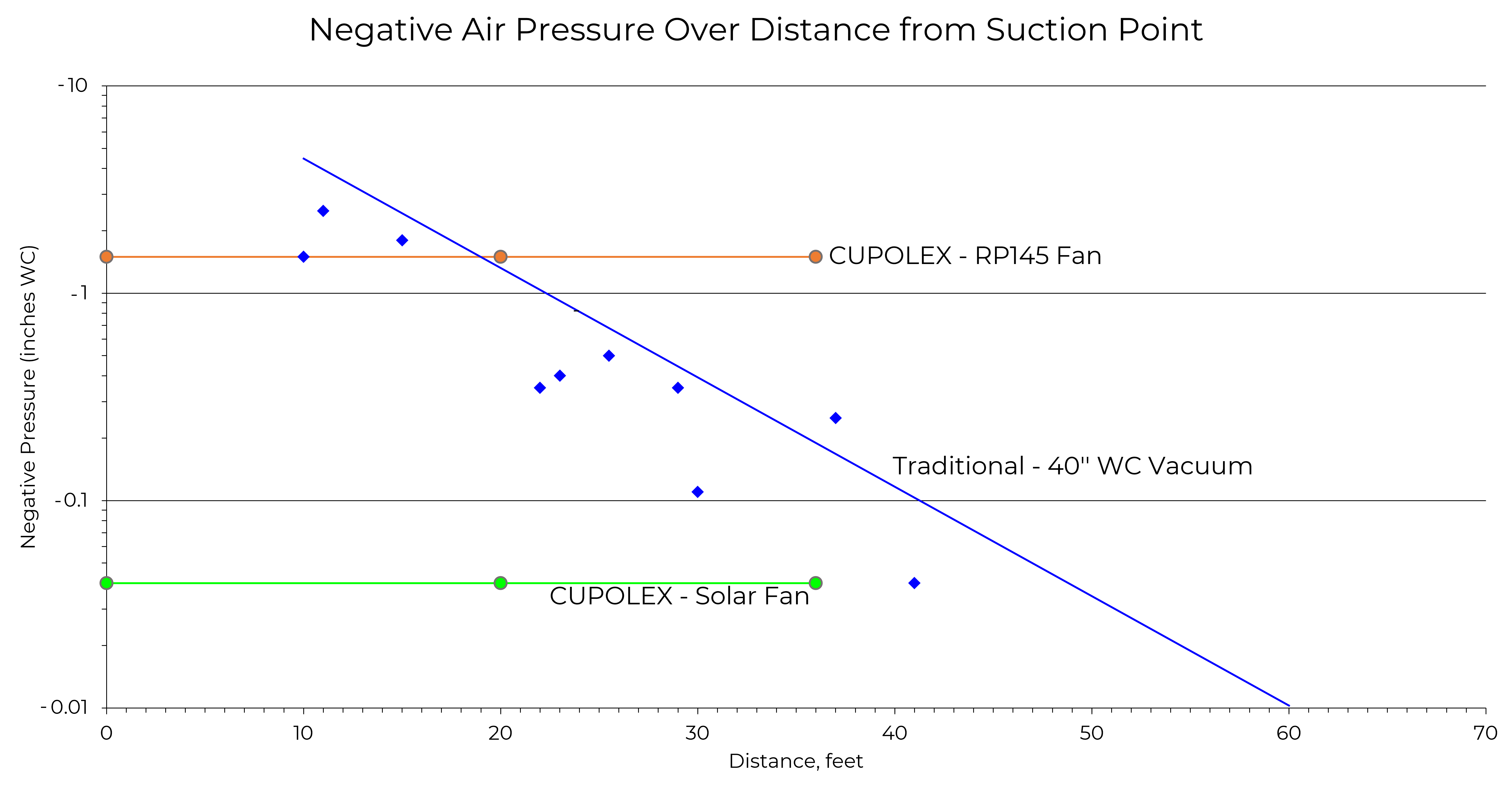

Soil gas mitigation is increasingly considered as a pre-emptive strategy at sites impacted with volatile organic compounds (VOCs), radon or naturally-occurring biogenic gases (e.g. methane). For new building construction, there is a range of possible mitigation solutions, which often involve modification of the building envelope in contact with soil to incorporate soil gas venting and/or barrier systems. CUPOLEX® aerated sub-floors provide a sustainable approach for soil gas mitigation and are more permeable than gravel layers, and thus are more efficient in term of venting characteristics.

While there are numerous reasons why the CUPOLEX® system outperforms the standard liner or gravel layer SSV system, there are three critical factors that make the CUPOLEX® system the superior system for your project:

These factors are:

- More effective venting,

- Constructability

- Minimal long-term maintenance costs.

FEATURES

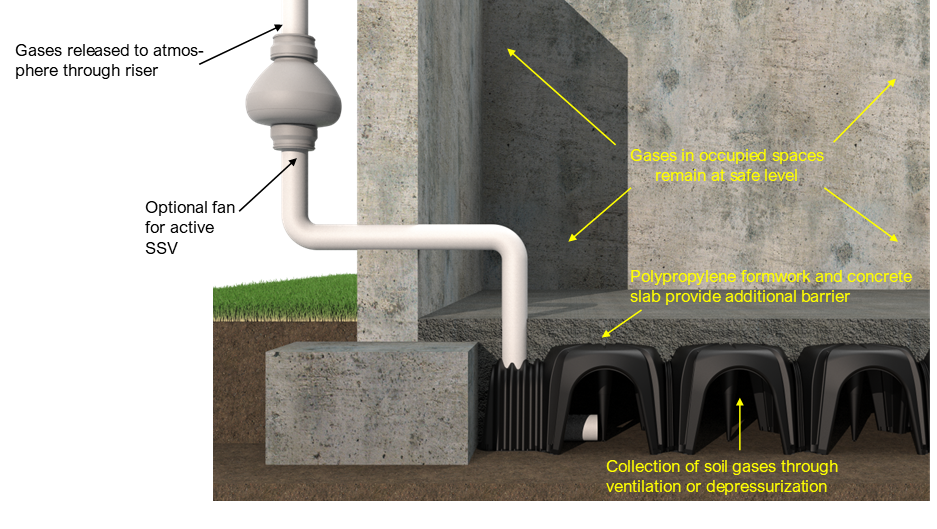

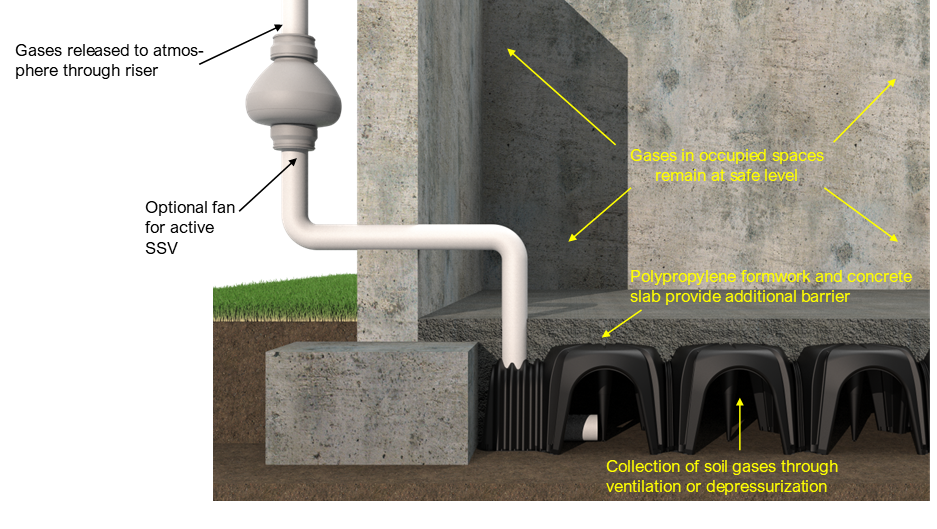

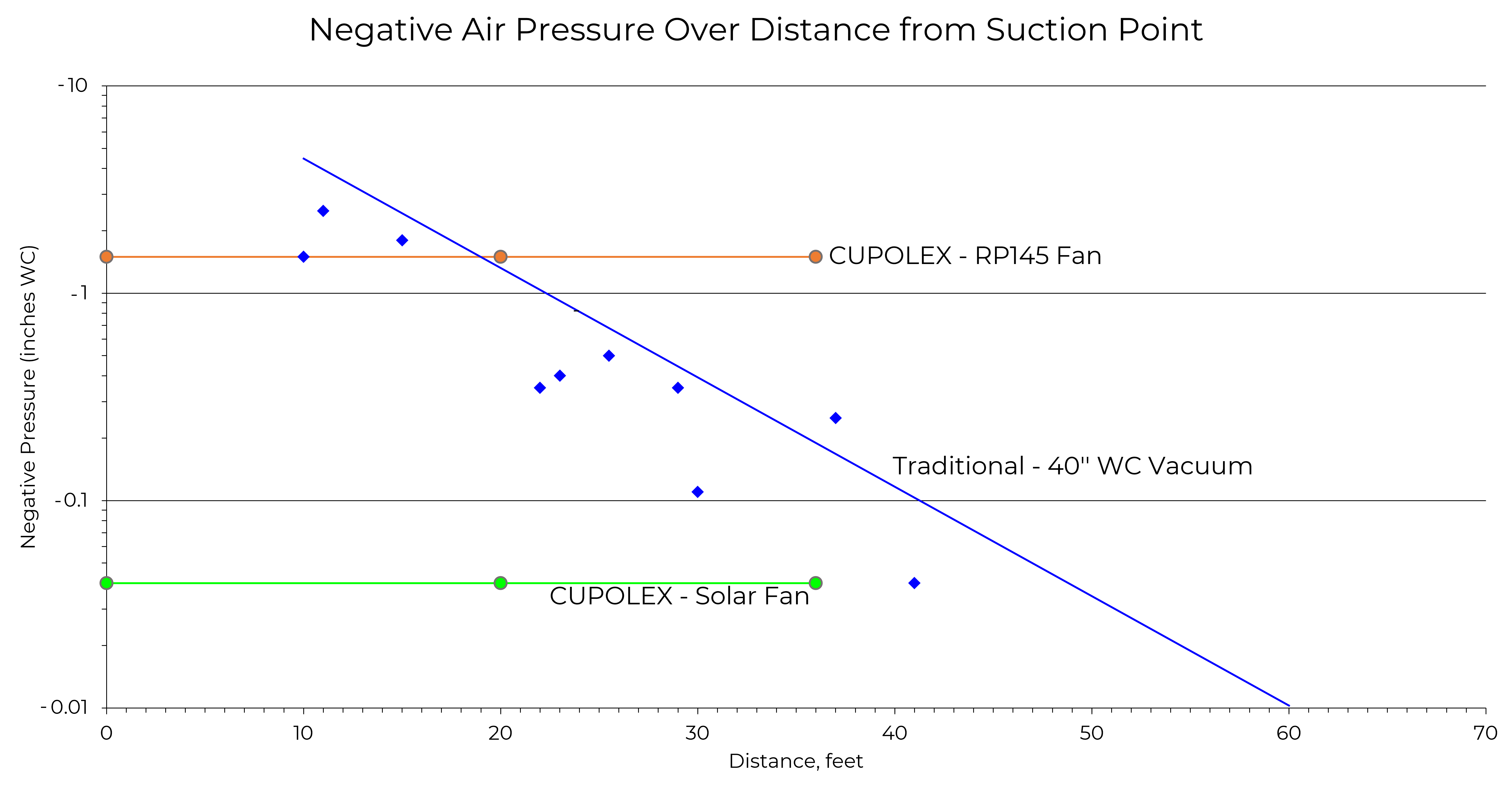

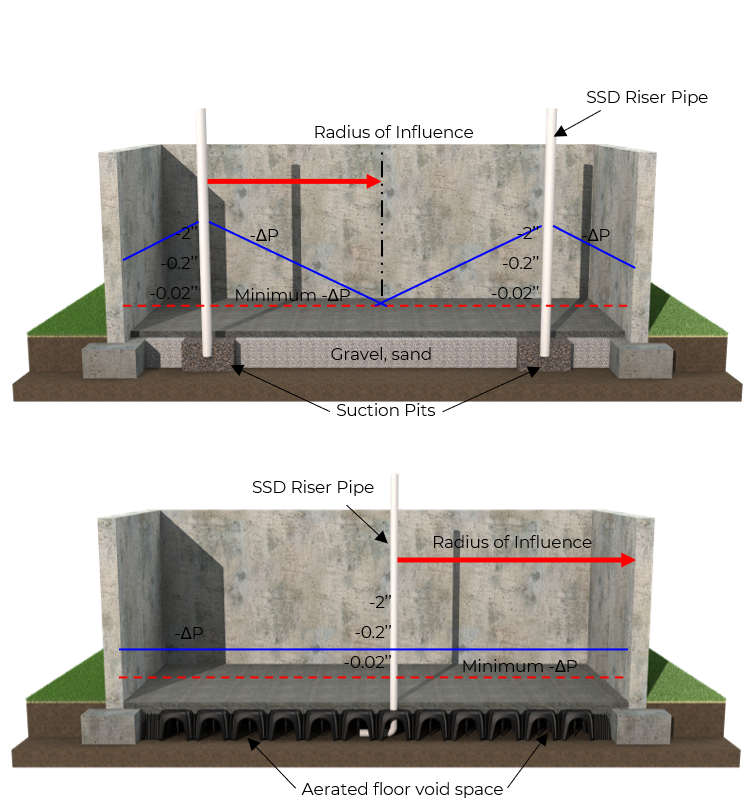

CUPOLEX® aerated floor systems control vapour intrusion by either diluting sub-slab concentrations to levels of no concern (the innate attenuation that any reasonable slab provides means that sub-slab concentrations do not have to be reduced to indoor air action levels), or by depressurizing the sub-slab void space to prevent upward flow of air into the building.

Advantages of CUPOLEX® sub-floor venting include:

- Provides a substantially more efficient under-slab void network than less efficient pipe and gravel venting layers

- More efficient venting

- Passive venting potential

- CUPOLEX® floors do not require membranes

- Low capital cost

- Fast assembly and can be installed by any concrete slab contractor or forming contractor

- The ability to cut the slab at any location and easily repair

- The ability to easily test, monitor and enhance performance

Applications

CUPOLEX® aerated floor systems can be designed for any type of building foundation construction. CUPOLEX® provides excellent flexibility in working with new construction or remodeled building layouts. The main characteristics of the forming system are speed and simplicity, with maximum benefits being realized when the CUPOLEX® system is engineered during the early design stages in assessing site and soil conditions and considering elevations of various sections of the slab area that may have to be raised. For example, if strip footings, walls or other typically formed sections can be incorporated within the system, cost savings and environmental benefits can be realized.

- Grade supported Floor Slabs

- Slab on grade PT foundations

- Raised floor slabs on Raft Foundations

- Foundation supported structural floor slabs

How CUPOLEX® Mitigation Systems Protect Buildings from Vapour Intrusion

- Provides a highly efficient under-slab void network for a more effective application of SSD, at a lower cost than the less efficient pipe and gravel venting layers.

- Provides a far more efficient, effective, and predictable medium for moving air than soil.

- Provides new opportunities for passive venting, with a network of open voids that allows air to move much more easily under natural thermal gradients or wind.

- Aerated floor system that rely on ventilation or depressurization (diverting and diluting the vapours) do not require membranes.

- Mitigation systems that result in the dilution of vapours below the floor and whose performance can be monitored and controlled (e.g., through fan operation and pressure measurements) have the advantage of not allowing vapour concentrations and pressures to build immediately below the building, which is not always the case with barrier systems.

- CUPOLEX® can provide cost effective pre-emptive mitigation control measures in new buildings and homes while saving concrete usage, reducing building cycle time, and minimizing engineered fill requirements.

Customized Design Package

Design Application Analysis – Our firm helps clients determine the Engineered CUPOLEX® system solutions that address specific site needs.

Value Engineering – CUPOLEX® works with value-engineering at the forefront of each project. We provide the best alternatives for every project.

Structural Systems Evaluation – Every project is unique. Our team reviews multiple structural CUPOLEX® systems to determine the best fit for each project.

Preliminary Structural Design – We work with our clients and their designers to determine the performance of a given CUPOLEX® structure under the prescribed loads and/or other effects or requirements while using principles of statics, dynamics and mechanics of materials to determine the size and arrangement of CUPOLEX® structural elements.

Material & Cost Estimating – Our collective experience helps us to provide our clients with material recommendations to reduce costs while maintaining the function of the CUPOLEX® structure.

Engineered Design Drawings – Issued for construction (IFC) and supported with FEA structural calculations, PE stamp, construction documents and specifications.

CUPOLEX® Installation Shop Drawings – With detailed CUPOLEX® formwork installation procedures issued to contractors.

Onsite Support – Construction training, monitoring and inspections for successful construction, and we present the information in a comprehensive report.

Construction Administration – We provide responses to request for information and interpretation of CUPOLEX® design drawings, with completion statements and regulatory compliance reporting where required.

USEFUL INFORMATION

Brochures

Process

VI Mitigators ![]()

Environmental Engineers ![]()

Architects ![]()

Structural Engineers ![]()

Municipalities ![]()

Residential Developers ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()

USEFUL INFORMATION

Brochures

Process

VI Mitigators ![]()

Environmental Engineers ![]()

Architects ![]()

Structural Engineers ![]()

Municipalities ![]()

Residential Developers ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()