ENGINEERED FLOORS

For Freezer and Cold Room Facilities

Freezer Floors – Ground Heave Solutions

Frost heave is a term commonly used to describe the displacement of structures caused by ice depositing underneath all or portions of structures operating constantly at low temperatures. Most refrigerated facilities are constructed with a slab-on-grade. In cases where the slab persistently operates below freezing (0°C/32°F), frost from moisture in the soil will form underneath the slab unless some form heat below the slab is provided. If the sub-slab is not heated, frost heave will not only eventually destroy the slab but also create other significant structural problems within the facility.

A properly designed CUPOLEX® passive or mechanically heated aerated concrete floor will provide sufficient heat to prevent frost formation under the slab; thereby preventing structural failures while minimizing the parasitic heat gain to the refrigerated space.

DESIGN FEATURES

- The mechanical or passive air distribution below CUPOLEX® floors is engineered to guarantee an unrestricted air flow below the entire concrete slab.

- In warmer climate areas, the engineered CUPOLEX® floor can be easily vented as a passive or active system using outside air

- Significantly reduces moisture that may condense inside the CUPOLEX® void space

- Maximum amount of heat entering the subsoil

- Under-floor heat can be supplied from outside air, warm exhaust air from a process equipment, or any other conveniently located space.

- Provides additional protection and better temperature control with heated air

- Allows ventilating from a furnace/makeup air unit or recover heat from the hot gas coming off the refrigeration system.

- Can be designed as a “closed” systems, meaning the air used in the under-floor system is recirculated after adding heat and dehumidifying.

- Allows the use of a fan to aerate the sub-floor network

- Can use heat reclaimed from refrigeration system

BENEFITS & ADVANTAGES

- Easy to inspect

- Simple design and lower cost than other electric, hydronic heating systems or vented piping systems

- Minimises maintenance

- No risk of plugging of conventional pipe branches by frost, ice, or other debris.

- Energy cost is less than electrical resistance

- No environmental concerns of leaking glycol into the soil

- Manufactured to ISO 9001:2015 high quality standards

APPLICATIONS

- Refrigerated freezers (distribution and long-term storage)

- Blast freezers (spiral freezers, blast cells, hardeners, etc.)

- Ice rinks

- Curling sheets

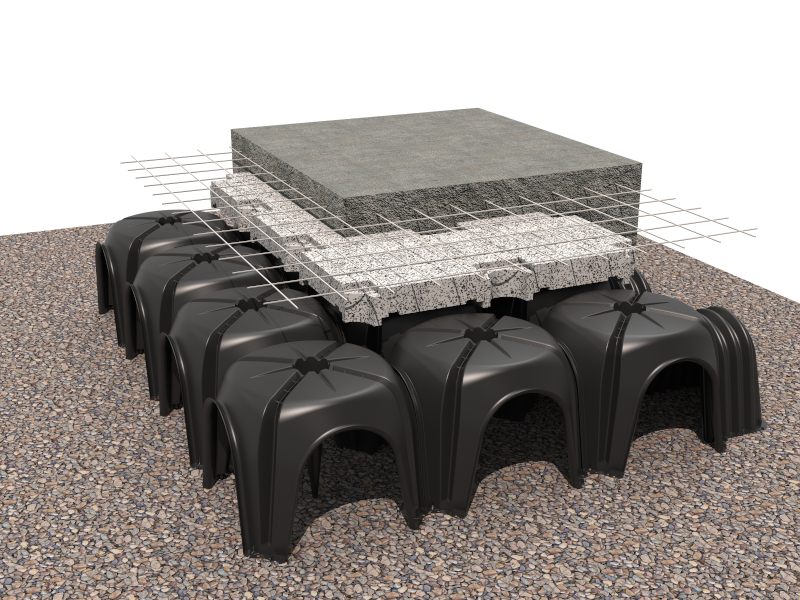

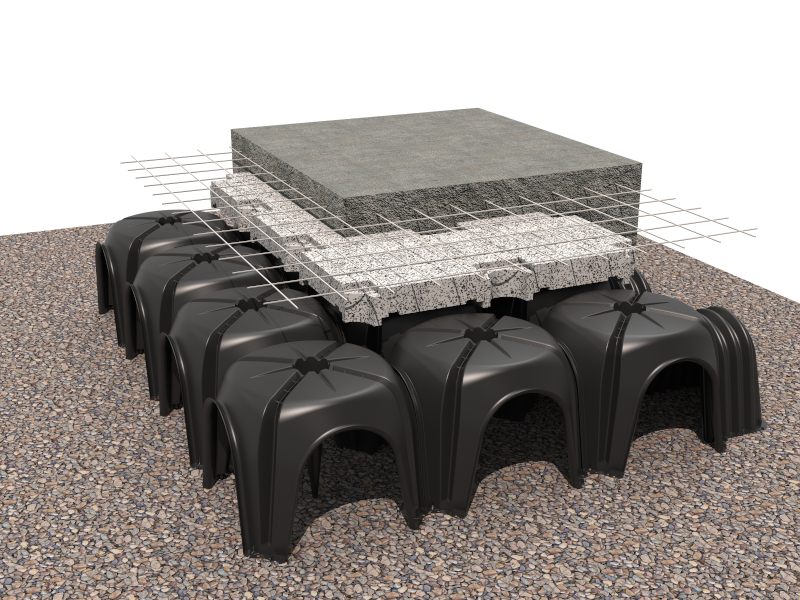

Engineered Isol-Cupolex® System

Cupolex offers unique and cutting edge engineered floor systems options for freezer and cold facilities, such as the pateneted Isol-Cupolex® system.

The engineered Isol-Cupolex® insulated crawl space is designed to create an insulated passive or active vented subfloor as a monolithic concrete pour, which significantly saves time and construction cost, compared to a two-pour insulated concrete floor slab. The form-based concrete geometry created by the engineered Isol-Cupolex® does not weigh on the insulation but the loads are transferred directly to the supporting subbase.

Customized Design Package

Design Application Analysis – Our firm helps clients determine the Engineered CUPOLEX® system solutions that address specific site needs.

Value Engineering – CUPOLEX® works with value-engineering at the forefront of each project. We provide the best alternatives for every project.

Structural Systems Evaluation – Every project is unique. Our team reviews multiple structural CUPOLEX® systems to determine the best fit for each project.

Preliminary Structural Design – We work with our clients and their designers to determine the performance of a given CUPOLEX® structure under the prescribed loads and/or other effects or requirements while using principles of statics, dynamics and mechanics of materials to determine the size and arrangement of CUPOLEX® structural elements.

Material & Cost Estimating – Our collective experience helps us to provide our clients with material recommendations to reduce costs while maintaining the function of the CUPOLEX® structure.

Engineered Design Drawings – Issued for construction (IFC) and supported with FEA structural calculations, PE stamp, construction documents and specifications.

CUPOLEX® Installation Shop Drawings – With detailed CUPOLEX® formwork installation procedures issued to contractors.

Onsite Support – Construction training, monitoring and inspections for successful construction, and we present the information in a comprehensive report.

Construction Administration – We provide responses to request for information and interpretation of CUPOLEX® design drawings, with completion statements and regulatory compliance reporting where required.

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()