ENGINEERED

Structural Concrete Floors

OVERVIEW

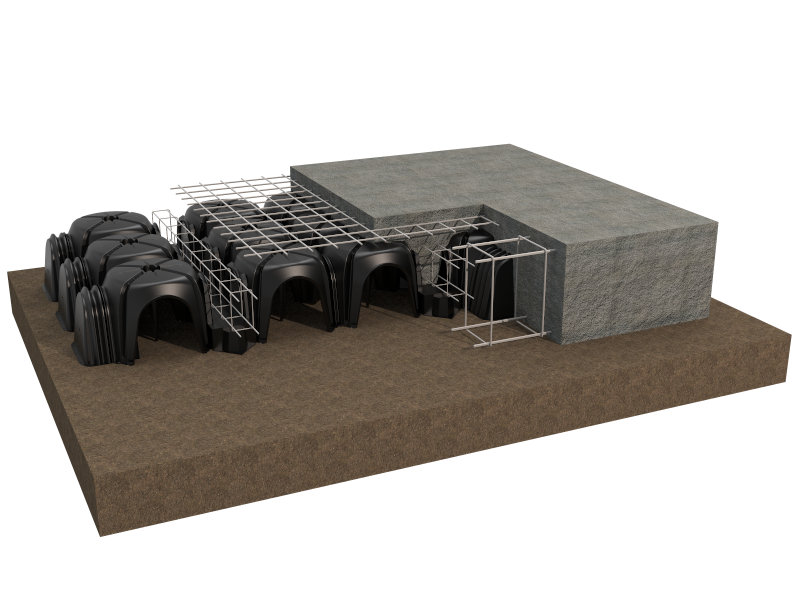

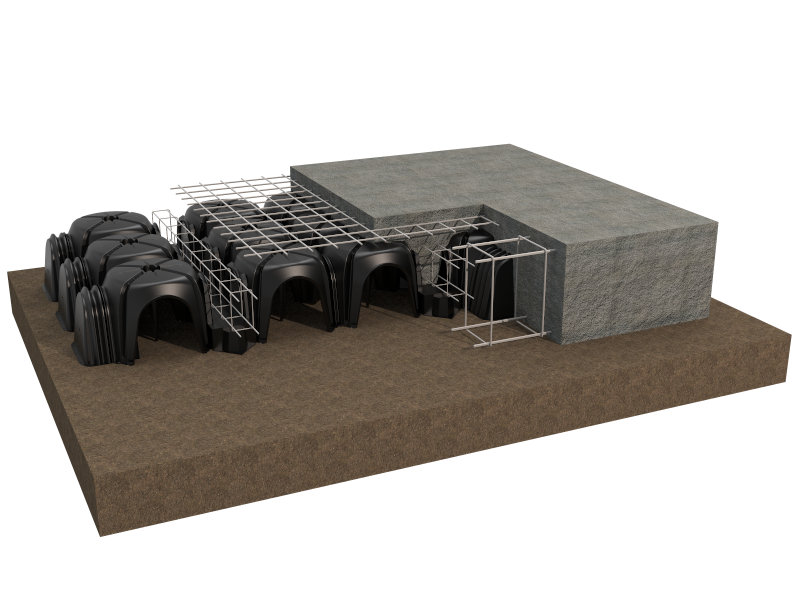

Traditional old-fashioned void forming systems for in-situ ground slabs and beams, subslab gravel drainage layers, and lightweight or imported engineered fill are increasingly being replaced by engineered CUPOLEX® structural systems: a quicker and less labor-intensive alternative. A trend that is encouraged by the emphasis on fast track build programs, lowering construction costs and a shortage of skilled tradesmen. Reacting to this trend, CUPOLEX® has developed a complete design and supply service for an extensive range of slab formwork systems.

APPLICATIONS

There may be many reasons for suspending a floor slab that may include:

- Unsuitable ground conditions such as very low bearing pressures

- Expansive/swelling soils

- Predicted post construction settlement of the subbase

- Bridging over public storm water and sewer lines

- Slope stability issues

FEATURES

- There are significant cost savings to the Builder, Designer, and their Client by using an engineered CUPOLEX® formed concrete slab.

- A well engineered CUPOLEX® designed structural slab for residential, industrial, commercial, and institutional applications in sites with structural site challenges and contaminated and low bearing soil conditions, can provide many advantages for the sustainability, constructability and economics of the project.

- One-way or Two-way stiffened slab on grade with integrated perimeter and interior grade beams or drop panels

- Can be designed for long spans up to 10m (30ft)

- Pile or Pier numbers may be optimized to limit additional costs.

- Cupolex structural slabs can be designed to be supported by any deep foundation system such as concrete, steel or timber piles, caissons, geo-piers, stem walls, and grade beams.

- Each structural CUPOLEX® floor slab is specifically designed to suit site conditions

Customized Design Package

Design Application Analysis – Our firm helps clients determine the Engineered CUPOLEX® system solutions that address specific site needs.

Value Engineering – CUPOLEX® works with value-engineering at the forefront of each project. We provide the best alternatives for every project.

Structural Systems Evaluation – Every project is unique. Our team reviews multiple structural CUPOLEX® systems to determine the best fit for each project.

Preliminary Structural Design – We work with our clients and their designers to determine the performance of a given CUPOLEX® structure under the prescribed loads and/or other effects or requirements while using principles of statics, dynamics and mechanics of materials to determine the size and arrangement of CUPOLEX® structural elements.

Material & Cost Estimating – Our collective experience helps us to provide our clients with material recommendations to reduce costs while maintaining the function of the CUPOLEX® structure.

Engineered Design Drawings – Issued for construction (IFC) and supported with FEA structural calculations, PE stamp, construction documents and specifications.

CUPOLEX® Installation Shop Drawings – With detailed CUPOLEX® formwork installation procedures issued to contractors.

Onsite Support – Construction training, monitoring and inspections for successful construction, and we present the information in a comprehensive report.

Construction Administration – We provide responses to request for information and interpretation of CUPOLEX® design drawings, with completion statements and regulatory compliance reporting where required.

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()