ENGINEERED

Structural Post-Tensioned Slab-on-Grade

OVERVIEW

The problem of “expansive soils” is well known to engineers and builders. It affects construction sites in many sites around the world, and particularly those in the desert, Rocky Mountain and the mid-continent Regions in NA. To avoid the build-up of these potentially damaging forces, slabs and foundations must be designed to accommodate any ground movement that is anticipated.

Sites consisting of these types of challenging soils often require very rigid slab designs with appropriate protection measures due to the structural harm these types of soils can deliver.

A Quicker and Less Labour-Intensive Engineered Design

Traditional old fashioned void forming systems for in-situ ground slabs and beams used on expansive soil sites are increasingly being replaced by CUPOLEX®, a quicker and less labour intensive alternative – A trend that is encouraged by the emphasis on fast track building programs. Reacting to this trend, CUPOLEX® has developed a complete design and supply service for an extensive range of slab formwork systems that can be designed for sites with:

- Low levels of expansive soils

- Moderate to high levels of expansive soils

- Critical and hydro collapsible soils

- Low bearing and expansive soils

- Post tensioned slabs

- Monolithic slabs

Design Solutions for Expansive Soils

CUPOLEX® with its ancillary concrete form PONTEX® provides a self-supporting structure to form a ribbed slab foundation system. A one-way or two-way stiffened joist is designed as a ribbed slab-on-grade mat foundation with integrated perimeter and interior grade beams or drop panels. CUPOLEX® engineered slab foundations reduce the slab-soil contact area, provide a lighter but stiffer slab than a traditional trenched ribbed slab and have high punching resistance from arch concrete dome engineering principles. Concrete verifications are performed according to national and local standards by using conventional reinforcing bars or post-tensioning tendons.

FEATURES

- The structural design using the modular CUPOLEX® dome forms create floating or structural slabs with an under slab void that results in minimal concrete contact with the soil , provides a capillary barrier against moisture – yet uses less concrete and rebar than a standard slab with equivalent load bearing capacity.

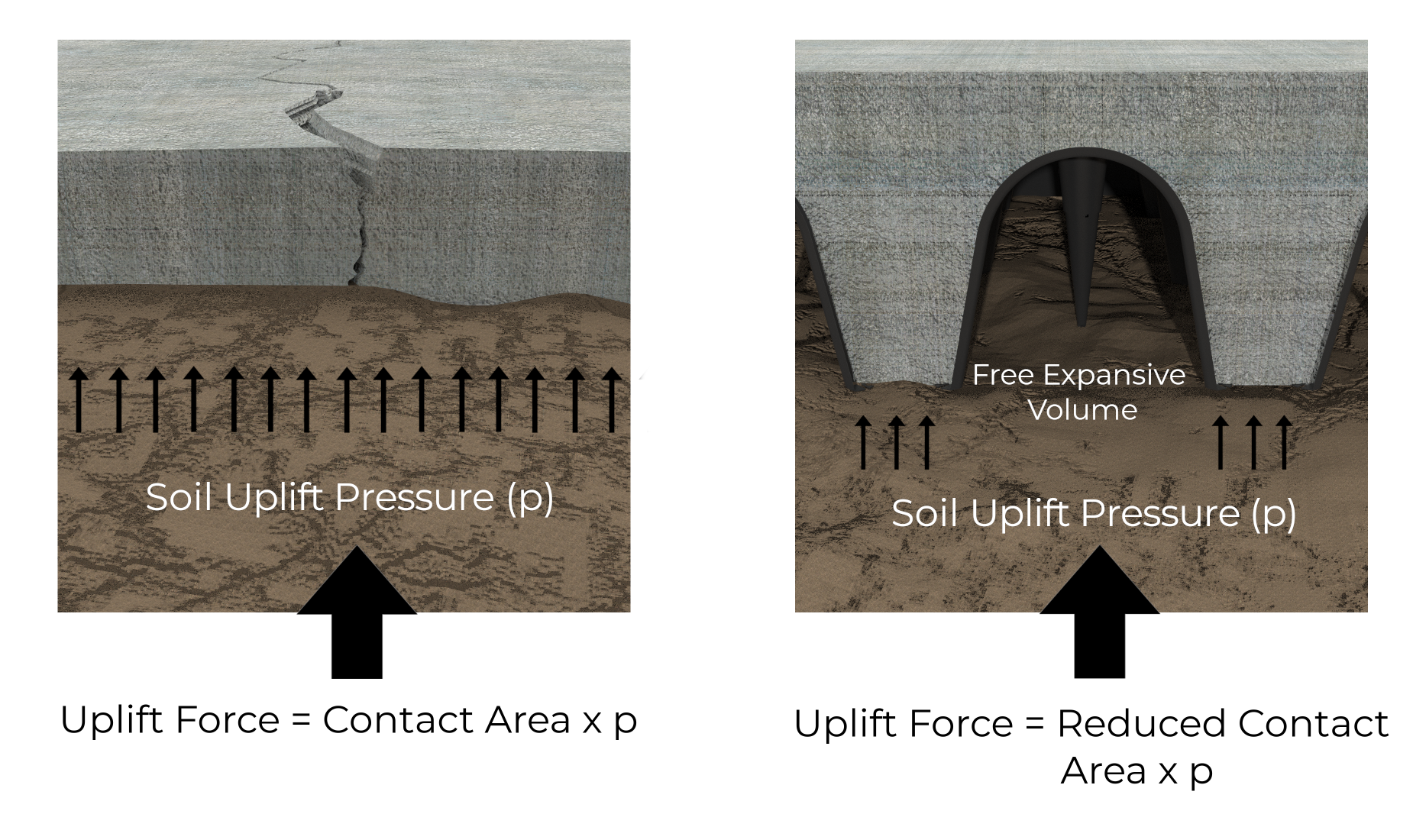

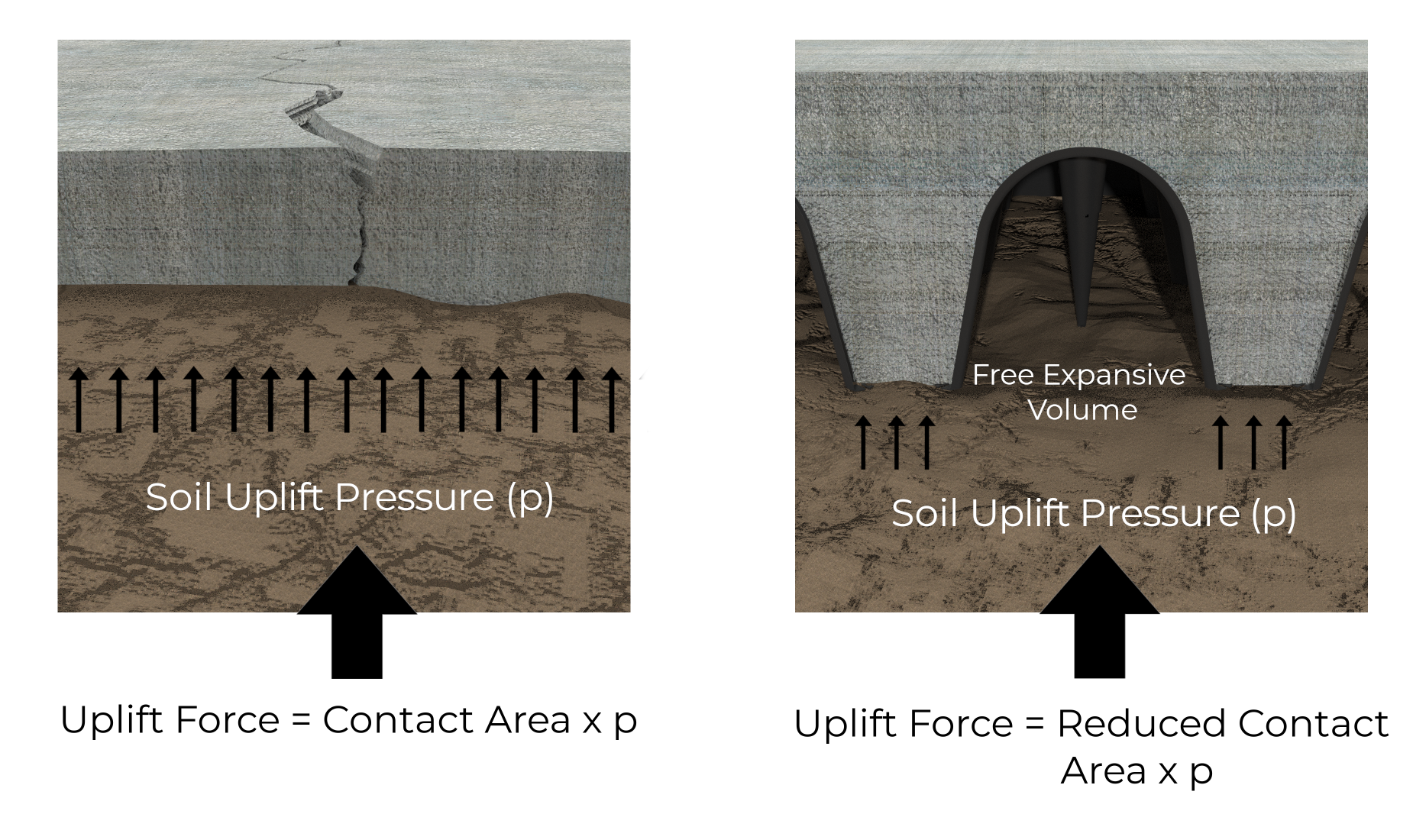

- The unique patented concrete geometry which CUPOLEX® forms minimizes the contact area on the soil which does not restrain the potential swelling of soils beneath the slab.

- The minimal concrete in contact greatly reduces the lateral and uplift forces that are produced compared to a conventional slab bearing on the soil throughout the total slab area.

- The CUPOLEX® slab in contact with the soil ranges from 4% to 10% of the total slab area creating a space into which soil can expand without causing damage.

- CUPOLEX® slabs do not restrain uplift forces and furthermore the dead loads of the concrete slab usually are greater than the uplift forces from the soil resulting in protection of the structure.

- In extreme swelling soil conditions, engineered suspended self-bearing CUPOLEX® slab foundations would be designed and constructed.

- Structural Design conforms to both International Building Code (IBC) and Post Tension Institute (PTI) specifications.

ADVANTAGES

- No presoaking of the pad is necessary.

- A post-tensioned or rebar reinforced concrete slab can be designed.

- Forms integrated concrete beams running throughout the footprint and perimeter.

- The completed CUPOLEX® engineered slab foundation design is supported by the subgrade like a raft foundation slab.

- Less contact area with the underlying soils and the voids formed by CUPOLEX® absorb heaving soils and eliminate significant structural cracking.

- Less contact area means less uplift pressure on the slab when soils heave.

- A CUPOLEX® ribbed slab foundation uses less concrete and steel and reduces excavation of soils and fill export when compared to conventional earth formed waffle slab designed systems.

- CUPOLEX® ribbed slab foundations reduce soils prep, materials, and building cycle time and often provide cost savings of up to 20% when compared to other foundation systems.

- Contributing to GREEN or LEED certified building

Customized Design Package

Design Application Analysis – Our firm helps clients determine the Engineered CUPOLEX® system solutions that address specific site needs.

Value Engineering – CUPOLEX® works with value-engineering at the forefront of each project. We provide the best alternatives for every project.

Structural Systems Evaluation – Every project is unique. Our team reviews multiple structural CUPOLEX® systems to determine the best fit for each project.

Preliminary Structural Design – We work with our clients and their designers to determine the performance of a given CUPOLEX® structure under the prescribed loads and/or other effects or requirements while using principles of statics, dynamics and mechanics of materials to determine the size and arrangement of CUPOLEX® structural elements.

Material & Cost Estimating – Our collective experience helps us to provide our clients with material recommendations to reduce costs while maintaining the function of the CUPOLEX® structure.

Engineered Design Drawings – Issued for construction (IFC) and supported with FEA structural calculations, PE stamp, construction documents and specifications.

CUPOLEX® Installation Shop Drawings – With detailed CUPOLEX® formwork installation procedures issued to contractors.

Onsite Support – Construction training, monitoring and inspections for successful construction, and we present the information in a comprehensive report.

Construction Administration – We provide responses to request for information and interpretation of CUPOLEX® design drawings, with completion statements and regulatory compliance reporting where required.

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Civil Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()

USEFUL INFORMATION

Brochures

Applications

Process

Structural Engineers ![]()

Civil Engineers ![]()

Architects ![]()

Flatwork & Forming Contractors ![]()

General Contractors ![]()